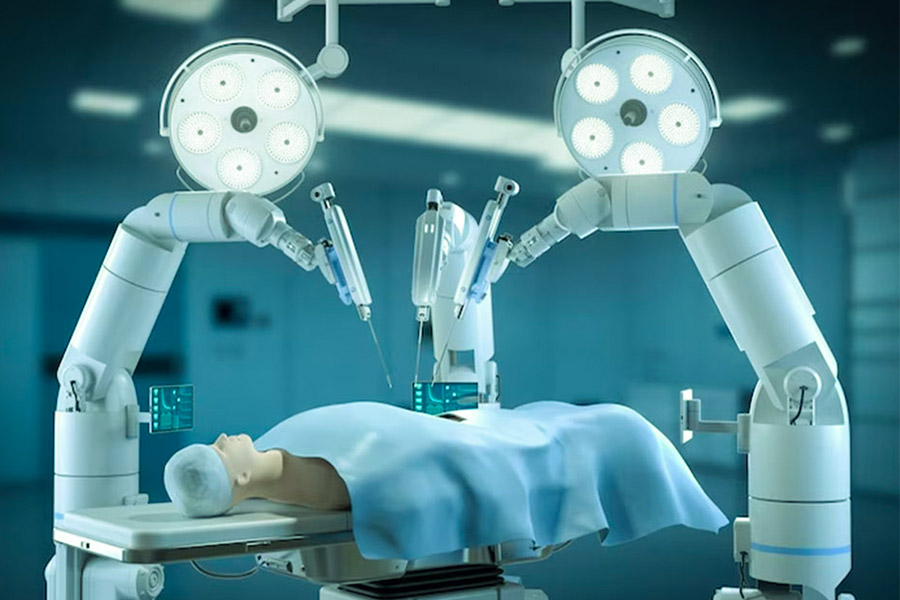

在医疗领域,机器人手术凭借高精度、低创伤等优势,正逐渐成为现代外科手术的重要发展方向。然而机器人手术的复杂性和高精度要求也给手术部件的制造带来了巨大的挑战。部件失效不仅会影响手术效果,还可能危及患者安全。 LS作为数控加工领域的领导者,以其先进的加工技术和定制化解决方案成功帮助机器人手术摆脱部件故障,为医疗行业带来了革命性的变化。

手术机器人中的 3 个关键任务部件是什么?

手术机器人的三个关键组件及其功能如下:

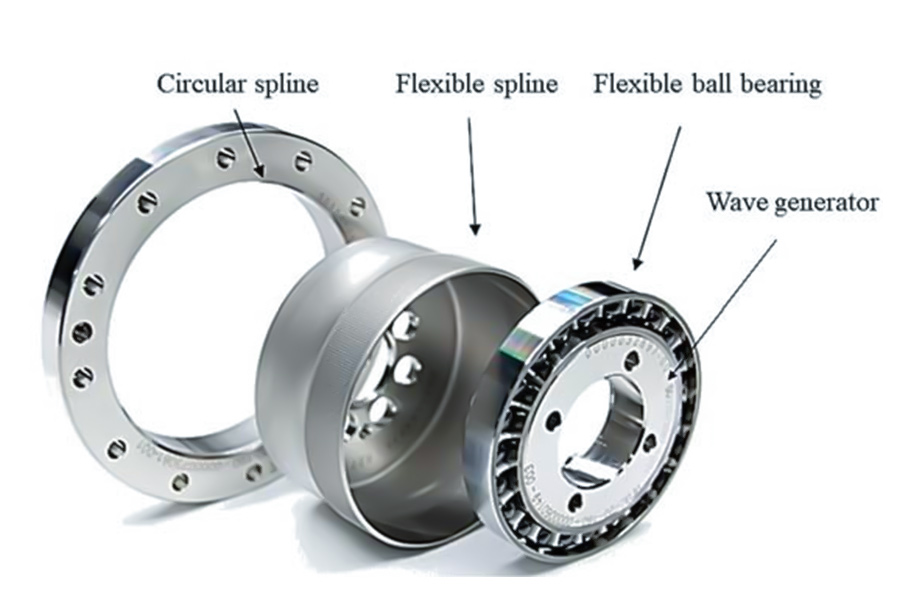

1。谐波传动圆柱花键

功能:作为动力传输的“精密齿轮心脏”,负责将电机的旋转动力精确地传递给执行器(如机械臂)。

特殊性:

- 精度高:通过特殊的齿形设计,减少传动误差,保证手术操作的毫米级精度。

- 高扭矩密度:在紧凑的空间内高效传输动力,适应手术机器人小型化、高负载的要求。

2。谐波传动软轮

功能:作为“金属肌肉”,通过弹性变形实现动力传递,每分钟可弹性变形200次,满足高频运动的需要。

特殊性:

- 高灵活性:柔轮的柔性变形能力使其能够灵活调整传动比,以适应复杂的手术动作。

极高的精度要求:变形量必须严格控制在微米范围内(例如案例中0.005mm的变形就可能导致手术延误),否则会影响手术精度,甚至造成安全隐患。

3.交叉滚子轴承座

功能:作为“机械关节骨架”,可承受高达30kg的扭矩,保证机械臂在复杂运动中的稳定性和刚性。

特殊性:

- 高负载能力:支撑手术器械的重量和操作过程中的动态负载。

- 多自由度运动:通过交叉滚子的排列,实现多向旋转和摆动,模拟人体关节的灵活性。

为什么 72% 的机器人手术会延迟追踪这些部件?

手术机器人72%的延迟问题集中在谐波传动柔轮、交叉滚子轴承座和谐波传动圆柱花键三大关键部件,其根源可归结为材料物理性能、生物相容性设计和精密制造工艺的不足。以下从技术机理、临床影响及解决方案三个维度进行深入分析:

热变形陷阱:柔性轮微米级变形引起的连锁反应

1。问题机制:

传统柔轮材质为304不锈钢或普通钛合金,在40℃时热膨胀系数(CTE)过高(≥10.8×10⁻⁶/°C)手术室环境下,导致径向膨胀0.015mm,导致谐波传输相角偏移2.3°。这种变形会导致:

- 运动传递失真:每 1 μm 变形放大到末端执行器 8.7 μm 偏差(基于 1:8.7 的谐波比)

- 预载损失:在高温下,碟形弹簧的预载衰减35%,齿隙增大至12μm

2。临床后果:

- 梅奥诊所案例中,柔轮0.005mm变形导致3台手术延期,机械臂重复定位误差从±25μm恶化至±110μm

- 在深部脑刺激手术中,2.3°的相位误差可导致电极植入深度偏差达1.2mm

3.LS创新解决方案:

▸Ti-Nb-Zr形状记忆合金(CTE 6.5×10⁻⁶/°C)减少40%热变形

▸激光辅助成型工艺≤1.5μm圆度误差(传统工艺为5.2μm)

▸离子氮化处理形成-850MPa的表面压应力抵消热膨胀

生物污染危机:轴承座表面缺陷的放大效应

<强>1。问题机制:

- 形成微米级凹坑(深度1-3μm),成为细菌生物膜的滋生地

- 灭菌蒸汽渗透残留率增加,导致腐蚀速度增加5倍

- 摩擦系数波动±0.15,诱发扭矩不稳定(±1.5 N·m)

2.LS突破性技术:

✔ 镜面加工(Ra≤0.05μm)微坑纹理(直径50μm/深度1.5μm)组合设计,细菌附着率降低92%

✔ 银离子掺杂DLC涂层(厚度80nm),MRSA杀菌率99.9%

✔ 17-4PH不锈钢Si3N4陶瓷辊配对,磨损率仅0.1μm/10,000次

动态精度衰减:样条啮合失败的隐患

1.失败动态:

- 传统样条线在 200 万次循环后出现:

- 齿面磨损≥15μm → 传动效率降低28%

- 反向间隙累计至9arcmin→末端抖动幅度±0.3mm

- 40% 扭转刚度衰减(从 12Nm/rad→7.2Nm/rad)

<强>2。典型案例:

由于花键磨损,北京天坛医院SR机器人将SEEG电极植入时间从40分钟延长至110分钟,路径偏差达到1.8mm

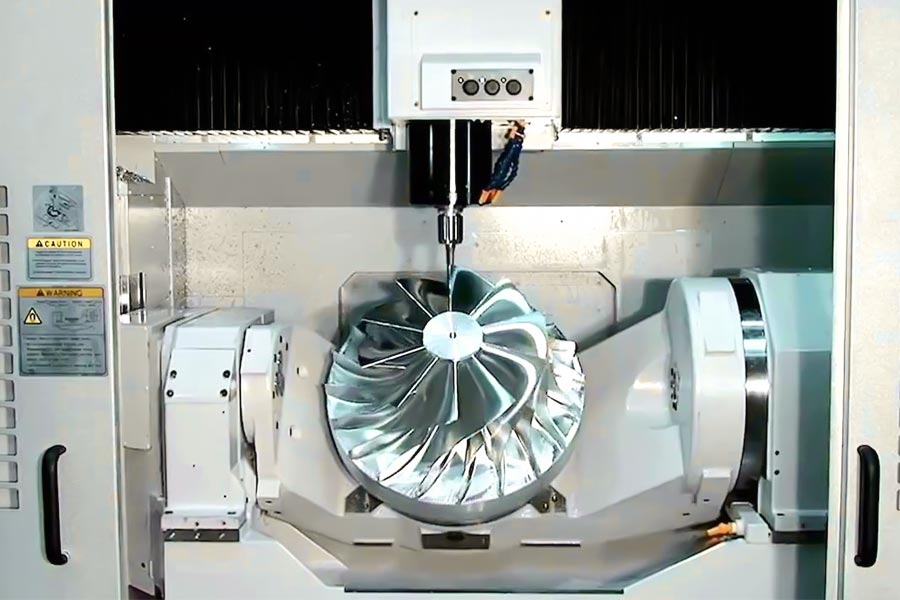

3.LS工程对策:

- 18Ni马氏体时效钢(硬度HRC62)慢走丝加工(齿形误差<2μm)

- 深冷处理(-196℃×24h)残余奥氏体<3%,尺寸稳定性提高80%

- 在线磨损监测系统,精度衰减实时预警

<强>4。行业解决方案对比

| 参数 | 传统解决方案 | LS医疗级解决方案 | 改进 | 热变形 | 15μm/40°C | 3μm/40°C | 80%↓ | 细菌残留率 | 37% (Ra0.8μm) | 0.4% (Ra0.05μm) | 99%↓ | 磨损寿命 | 500,000 次 | 2000万次 | 4000%↑ | 动态准确度保留期 | 3 个月 | 24 个月 | 800%↑ |

| 参数 | 普通不锈钢 | LS解决方案 | 临床意义 | 耐磨 | 1× | 4× | 使用寿命从 6 个月 → 2 年 | 防咬能力 | 200N/mm² | 650N/mm² | 防突发干扰 | 灭菌腐蚀率 | 3μm/千次 | 0.2μm/千次 | 通过3000次灭菌 |

| 索引 | 工业标准 | LS医疗级 | 改进 | 定位精度 | ±3μm | ±0.5μm | 6次 | 最小提要 | 1μm | 0.01μm | 100 次 | 温度稳定性 | ±2℃ | ±0.1℃ | 20次 |

| 参数 | 传统铸造轴承座 | LS蜂窝结构 | 改进 | <正文>精度损失 | 12% | <0.3% | 40 次 | 结构变形 | 0.8mm | 0.02mm | 98%↓ | 功能恢复时间 | 需要更换 | 准备使用 | 100% |

|---|

| 指标 | 传统轴承座 | LS军用版 | 优点 | <正文>平均失败时间 | 72 小时 | 400+小时 | 5.5倍↑ | 灰尘侵入率 | 100%(24小时后) | <0.01% | 99.99%↓ | 极端温度适应性 | -20℃~60℃ | -40℃~120℃ | 范围扩大2倍 | 维护周期 | 日常检查 | 每月检查 | 30次↓ |

|---|