Milling machines are an indispensable cornerstone of modern manufacturing. What exactly are their core functions?

Milling machines represent a core cornerstone of modern manufacturing. What are their primary functions?

A milling machine is a machine tool used to cut and shape metal, wood, and plastic. It does this by moving a cutting tool across a stationary workpiece. Since it uses smooth and controlled force, the process allows one to achieve precise pieces and complex designs. A milling machine might be your best option if your business or industry requires high precision and accuracy.

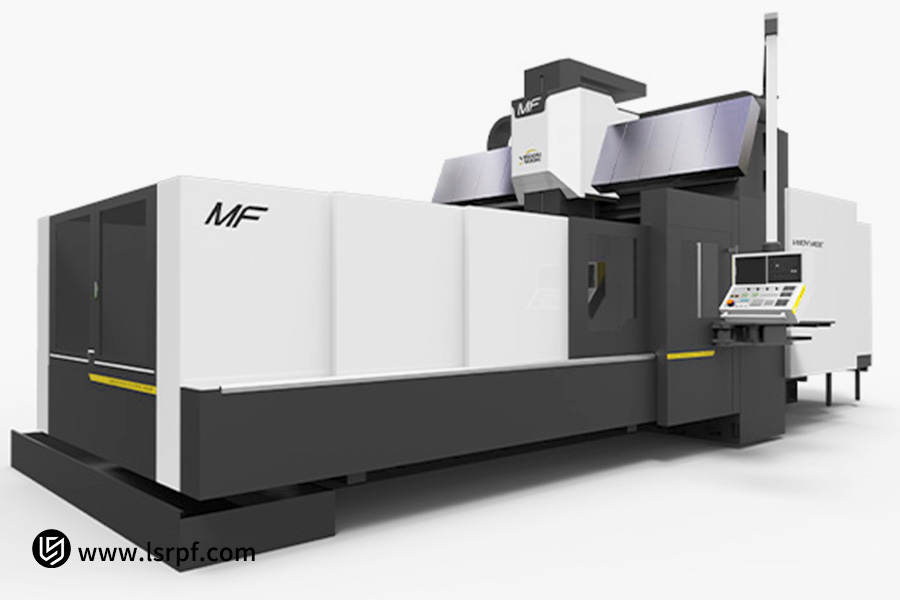

Technically speaking, a milling machine is a machine tool that employs a high-speed, multi-tooth cutting tool (milling cutter) to remove material accurately from a workpiece securely clamped on a worktable. This proven-and-tested industry workhorse can readily machine flat surfaces, curved surfaces, grooves, cavities, holes, and complicated three-dimensional contours and thus is a versatile machine tool utilized for making parts, molds, aircraft parts, and more. The next article will delve into its working laws, types, applications, uses, and advantages, providing a complete answer to the question, "What is a milling machine used for?"

Quick Reference: Choose Your Tap at a Glance

| Core Functions | Processing Targets | Major Industry Applications | Technical Features |

| Cutting materials using rotating tools | Metals, plastics, wood, composites, etc. | Mechanical manufacturing, aerospace, automotive, molds | Multi-axis linkage, high precision, complex surfaces |

| Manufacturing of planes, slots, holes, gears, etc. | Complex geometric workpieces | Electronics, medical devices, energy equipment | Programmable control (CNC), automation |

| Creating precision parts and prototypes | Customized parts, mass-produced components | Research, education, craftsmanship | Versatile, efficient, and flexible |

This guide will completely break the stereotype of milling machines and take you to explore its core functions, working principles, materials and shapes that can be processed. Through a real case analysis, it will reveal how it can turn a piece of 'blank' into an amazing precision part and why its value far exceeds 'cutting metal' itself.

Why Trust This Guide? Practical Experience From LS. Experts

Because we are not theorists, we are practitioners.

At LS. Precision Manufacturing, we run a range of milling machines, from manual to five-axis, daily, machining thousands of components. If milling machines merely "cut metal," we could not fulfill our customers' varied requirements, ranging from precision components with ±0.01mm tolerance to large, intricate structures. We recognize that the technical challenge and expense of milling a plain flat surface are quite different from milling an impeller with free-form surfaces.

We also machined a palm-sized titanium implant prototype for a customer that was required to have a mirror finish and contained hundreds of microscopic features. The volume of material removal could be small, but the machining accuracy, surface finish, and requirement for process control were extremely high. This guide is a summation of decades of field experience running milling machines and troubleshooting thousands of manufacturing problems.

The Basic Principle of Milling Machine Operation

The basic working principle

A milling machine is to machine a workpiece with a rotating tool. The rotation of the tool is the primary motion, and the movement of the workpiece is the feed motion. Milling machines can execute a wide range of machining processes, such as planes, grooves, gears, threads, and curved surfaces.

Operating procedure of the milling machine

It's a carefully choreographed "mechanical dance." To machine a flat surface, for instance, the workpiece is clamped to a worktable that travels on the X/Y/Z axes. A milling cutter is attached to a high-speed spindle. The operator employs the control system to establish parameters like spindle speed, feed rate, and depth of cut according to the machining operation.

The milling cutter, mounted on the spindle, begins to rotate at high speed, generating cutting force. The milling cutter's cutting edge, rotating on the worktable, contacts the fixed or moving workpiece, removing material through relative motion while simultaneously moving in a predetermined direction and speed, gradually bringing the workpiece closer to the milling cutter.

The milling cutter's cutting edge continuously engages the workpiece material, moving linearly or curvilinearly relative to the tool, achieving continuous cutting. Excess metal is removed, and as the worktable continues to advance, the workpiece surface is gradually smoothed.

The function of the spindle

It is to drive the workpiece or tool by rotary motion in machining. The spindle is one of the most important components of most machine tools, such as lathes, milling machines, and drilling machines. Not only does it determine machining speed and accuracy, but also it directly affects the quality of the machined surface and the accuracy of its shape.

Main Types of Milling Machines

| Milling Machine Type | Maximum Spindle Speed (per minute) | Workbench Size (mm) | Maximum Workpiece Weight (kg) | Application |

| Vertical Milling Machine | 4,000 | 1000 x 500 | 500 | General machining, drilling |

| Horizontal Milling Machine | 3,500 | 1200 x 600 | 800 | Slotting, gear cutting |

| Universal Milling Machine | 5,000 | 1100 x 550 | 600 | Complex parts processing |

| Bed Milling Machine | 3,000 | 1400 x 700 | 1000 | Heavy machinery |

| CNC Milling Machine | 10,000 | 800 x 400 | 300 | Precision parts |

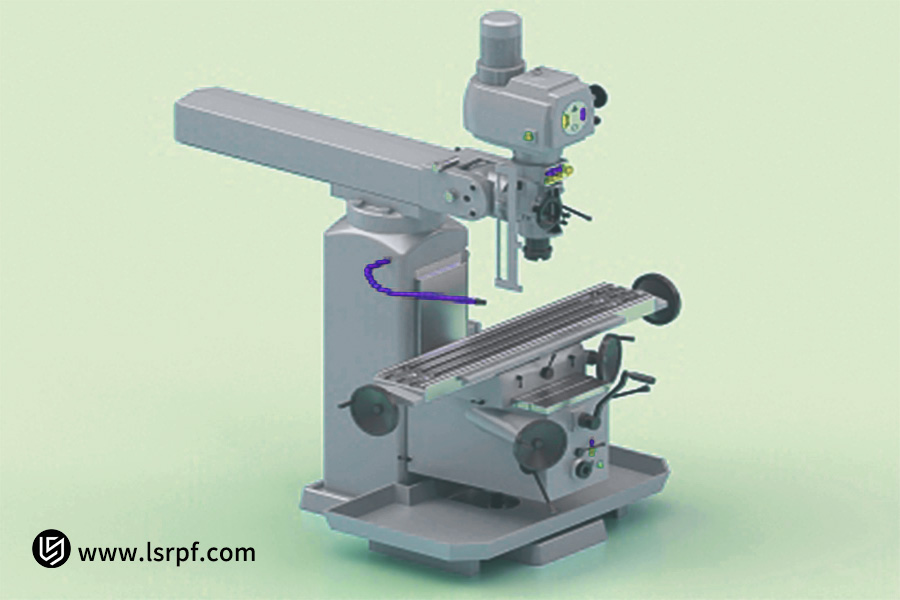

Vertical Milling Machine

The spindle travels in the Z-axis vertically, where the cutting tool also functions. The worktable moves mainly in the X/Y axes, enabling several operations without positional change, thereby enhancing flexibility. The other benefit of having the vertical spindle positioning is precision in drilling holes since a particular position of the tool on the workpiece is easily obtained.

These special design characteristics suit them to plunge cutting, in which the tool plunges straight into the material to produce a hole or recess. This is the most widespread form of milling machine, appropriate for surface milling, cavitation, and drilling.

Vertical mills are highly recommended for a wide range of applications, particularly in those areas requiring high precision and accuracy, such as aerospace and automotive. They can be used to shape, cut, and even drill complex parts.

Horizontal Milling Machine

Unlike vertical milling machines, the spindle of a horizontal milling machine is horizontal and parallel to the worktable, which moves in the X, Y, and Z axes. As such, it is suitable for heavy milling, machining lengthy workpieces, and multi-sided machining (with an indexing head). It excels at slotting and face milling. This arrangement provides more surface rigidity, so it is suitable for working on large, thick materials and performing challenging operations. It is also well-suited for operations with roughing and using multiple cutting tools at once. This machine plays an essential role in the production of large, high-accuracy components.

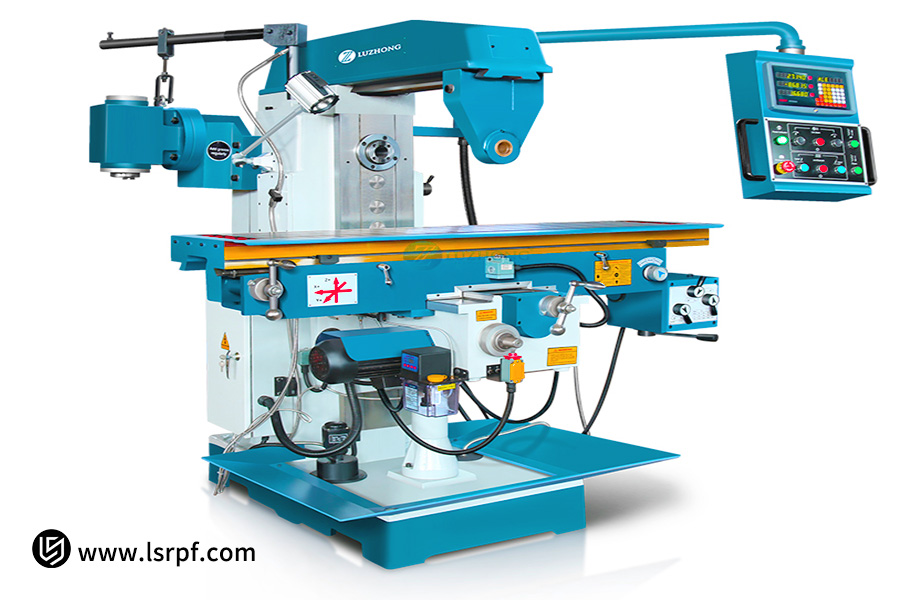

Universal Milling Machine

This heavy-duty, multi-purpose tool combines the capabilities of a vertical milling machine and a horizontal milling machine. The worktable can be tilted forward, offering the heavy cutting and drilling capabilities of a vertical mill, or swung sideways, impacting the worktable surface with the same force as a horizontal mill.

The worktable can rotate within the horizontal plane and move in multiple directions, expanding its capabilities for machining complex angles and spiral grooves, making it suitable for a variety of complex operations. It can also facilitate operations such as boring, cutting, shaping, and slitting, making this universal milling machine highly effective in performing a variety of flat and contour milling operations, significantly increasing production.

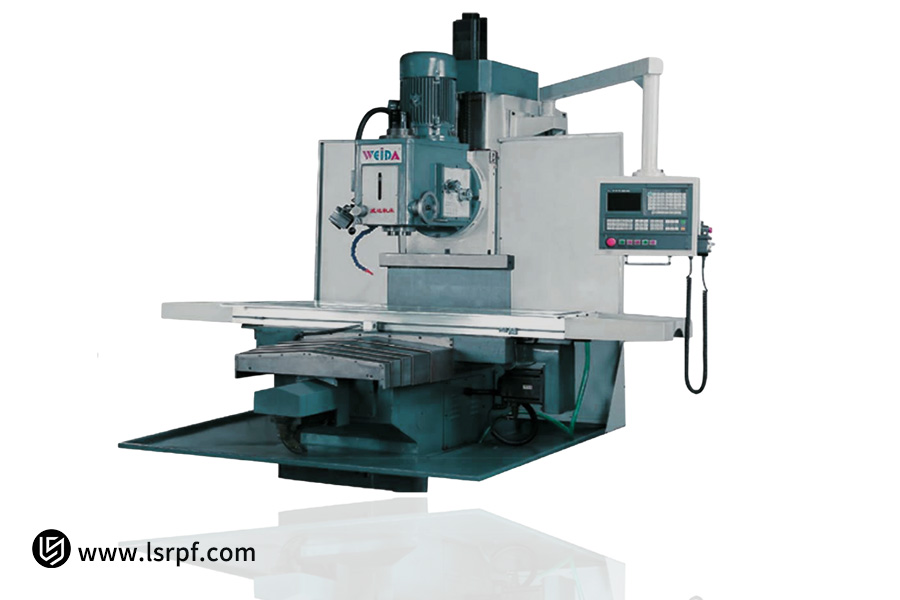

Bed-type Milling Machine

Bed-type milling machines have a stationary table, offering rigid support and are well suited for heavy milling operations. In contrast to other milling machines, wherein the spindle travels up and down on the Z axis, the table remains stationary and travels on the X and Y axes.

This structure greatly enhances the structural strength and rigidity of the machine, allowing it to accommodate heavy workpieces and to carry out operations involving high force.

CNC Milling Machine

The CNC milling machines are used in a computer numerical control (CNC) operation to manufacture metals, with computer programs controlling all axis motion, spindle speed, and feed rate. They are very rigid, offering close tolerances, and are ideal for high-tech work with mathematical calculations and the requirement to manufacture identically sized items. They enable high precision, the ability to machine complex shapes, and a great degree of automation. It is due to this that CNC milling machines are the standard today.

The Core Processing Capabilities of Milling Machines

| Face Milling | Machining the flat surface of a workpiece. |

| Contour Milling | Machining the edge contour or specific shape of a workpiece. |

| Slot Milling | Making straight slots, T-slots, dovetail slots, etc. of various widths. |

| Pocket Milling | Making closed or open grooves and cavities within a workpiece. |

| Drilling & Tapping | Utilizing the positioning accuracy and spindle capabilities of a milling machine to perform drilling, reaming, and tapping. |

| Surface Contouring | Machining complex three-dimensional surfaces using multi-axis machining (three or more axes). |

| Gear Cutting | Machining gear teeth using specialized milling cutters (such as gear milling cutters). |

| Engraving | Making text or designs on the surface of a workpiece. |

Application Areas of Milling Machines

Then, I will present before you the excellent uses of milling machines in various sectors such as mechanical manufacturing, mold manufacturing, aerospace, automotive production, electronics industry, medical devices, energy sector, prototype and rapid prototyping, and general workshops.

Mechanical Manufacturing

For mechanical manufacturing, milling machines are applied to machine many mechanical components, such as shafts, housings, brackets, connectors, gears, cams, connecting rods, etc. The high-precision machining of the milling machine ensures the dimension precision and surface quality of the components.

Mold Manufacturing

In mold production, processing of the mold requires extremely high surface finish and accuracy. Milling machines are extremely useful for machining complex mold cavities and cores, i.e., injection molds, stamping molds, and die-casting molds. CNC milling machines are most widely used for mold processing.

Aerospace

The aerospace sector demands the production of large volumes of high-strength, high-precision components, for example, engine and fuselage structures. Five-axis CNC milling machines and milling machines can efficiently process complicated aerospace components.

Automotive Manufacturing

In the automobile industry, milling machines are used for producing some of the most critical components, such as engine blocks and cylinder heads, transmission cases and components, axles, and chassis. CNC milling machine process efficiency can improve part precision and production efficiency.

Electronics Industry

Milling machines in electronics manufacturing create intricate circuit boards, precision enclosures, heat sinks, connectors and sockets, and components for semiconductor devices. They are well known for their accuracy, repeatability, and capability to make robust, durable components from extruded blocks of material.

Medical Devices

In the field of medical device production, milling machines are used to create surgical tools, orthopedic implants, dental tools and implants, prosthetic and exoskeleton prostheses, and robotic surgery instruments. With their ability to create intricate components with precise accuracy, CNC milling has become an important tool in the production of these life-saving devices.

Energy Sector (Electric Power, Gas, Oil)

In the energy sector, milling machines also play critical roles in oil, gas, and electrical power, including the machining of valves, turbine blades, and large structural components.

Prototyping & Rapid Prototyping

Milling machines also help in creating prototypes of products and can also create high-precision functional prototypes.

General Repair Shops

Milling machines in general repair shops are utilized to fix parts and also to make custom parts. They find common use across a range of disciplines.

Main Benefits of Utilizing a Milling Machine

| Versatility | It can carry out a range of machining operations (milling, drilling, boring, tapping, etc.) and machine a range of shapes. |

| Precision and Repeatability | CNC milling machines, especially, can provide micron-level accuracy and batch precision. |

| High Efficiency | Good cutting capability, especially when machining complex parts, is better than many other methods. |

| Complex Geometries | Multi-axis CNC milling machines are capable of processing intricate three-dimensional geometries that are hard to obtain by conventional means. |

| Good Surface Finish | Excellent surface quality can be achieved by selecting suitable tools, parameters, and processes. |

| Wide Material Range | It can work on metals (steel, aluminum, titanium, copper, etc.), plastics, composite materials, wood, etc. |

Case Study: Precision Milling Addresses Titanium Swing Arm Processing Bottleneck

Customer challenge

We encountered an engine racing startup company that needed to produce a small batch of 20 prototypes of titanium alloy valve rocker arms with complicated forms. These needed to have accurate surface contours, a cavity for weight reduction, critical tolerances of ±0.01mm, and a surface finish of Ra 0.8μm.

The limitations of traditional solutions

Conventional practices of wire cutting or manual polishing were extremely time-consuming (about 2 days per piece). While the products required by the customers were not able to stably meet the surface, precision and smoothness requirements, which caused serious delays in the project.

LS's innovative solution

We used a five-axis CNC milling machine to address their problem. The crown of this machine is its extremely precise, computer-controlled, high-speed, multi-edged tooling. With the inclusion of multi-axis (X/Y/Z/A/C) motion, it can accurately machine complex three-dimensional surfaces, cavities, and holes within one clamping.

Excellent results

As a result of the multi-axis capability of the milling machine and CNC precision, we managed to complete the first five prototypes in 18 hours. All sample sizes precisely matched the specifications of drawings (with tolerances at all times within ±0.005mm), surface finishes finer than Ra 0.6μm, and perfect uniformity on all 20 prototypes.

LS's value embodiment

This case demonstrates how LS. solves the customer's agony points for processing challenging specialty materials through the synergy of engineering analysis, materials science, and state-of-the-art manufacturing technologies. We not only provide machinery but also total process optimization solutions so that customers can overcome the limitations of traditional processes and achieve overall improvement in quality, efficiency, and cost savings so that they can focus on creating more core value.

FAQs

1. What's the difference between a milling machine and a lathe?

The fundamental difference is in the workpiece and tool movement. In a lathe, the work is made to rotate and a stationary tool translates linearly to cut cylindrical features. In a mill, the tool is made to rotate and a stationary or moving table translates the work in a feed direction in order to enable it to cut features like flat surfaces, curved surfaces, and grooves. Briefly stated, a lathe "turns circles," and a mill "mills faces, grooves, and contours."

2. Can a milling machine drill holes?

Yes, a milling machine can be used to drill holes. Attaching a drill head and controlling the Z-axis movement (spindle up and down), together with X or Y-axis positioning, a milling machine is able to accomplish drilling operations with a reasonable degree of accuracy. Moreover, the table of a milling machine is horizontal and vertical in motion, enabling it to perform different machining operations, including drilling, boring, and contouring.

3. How is a CNC milling machine better than a manual milling machine?

The biggest advantages of CNC milling machines over manual milling machines are that they can be repeatable and precise and can prevent human mistakes; they have strong capability to machine difficult-to-machine parts and are capable of achieving multi-axis synchronization; they are highly automated, which can reduce the amount of human operation and can be unmanned for a long time; at the same time, they are highly efficient, can optimize the path and traverse with high speed; in program-controlled production, they are convenient to exchange and repeat the manufacturing of the same part.

4. What materials can a milling machine process?

Milling machines can cut through many varieties of material, including different metals like steel, stainless steel, cast iron, aluminum, copper, and titanium alloys, and plastics like ABS, nylon, POM, and PEEK, composite, wood, and foam. The selection of the material to be milled on a milling machine depends on the selection of the suitable tool material, form, and cutting parameters.

Summary

Milling Machines – The Precision Power That Shapes Our Complex World

Milling Machines – The Precision Power That Shapes Our Complex World A milling machine is not only a cutting tool; it's the essential machine that converts design blueprints into precision solid parts. Its innovative "rotating tool + multi-directional feed" concept provides it with unmatched versatility, rendering it a definitive workhorse for machining flat surfaces, grooves, complicated contours, and curved surfaces. When your components exceed basic turning or drilling, demanding accurate geometry, close dimensional tolerances, and detailed surface features, a milling machine becomes your valuable production companion.

Does your part have intricate shapes? Does it need high-precision flat surfaces or contours? Don't hesitate to determine what machining process is most suitable for you! Send your part drawing or 3D model to our team of experienced engineers today. We'll analyze your design, suggest the best milling solution, and give you a quick, transparent CNC machining quote! Allow our milling experience to speed up your project.

In the face of these higher challenges, LS's CNC turning service is your indispensable ultimate "tool". It represents industrial-grade precision, unparalleled repeatability and efficient productivity, allowing your design ideas to be perfectly, consistently and efficiently realized. Choosing LS is to inject industrial-grade precision power into your extraordinary craftsmanship.

Upload your design drawings now and get an instant CNC turning quote (cnc turning price), let LS be your strong backing in pursuit of ultimate woodworking precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com